Blog

The Ultimate Guide to Building a Mobile Tool-Storage System for Your Workshop and Work Vehicle

As a craftsman, my workshop is my sanctuary. But I’ve seen countless shops and work vehicles drowning in an unorganized mess of tools, or suffocating under a rigid wall of generic toolboxes. Neither extreme sparks joy, am I right?

Here at Robert Kline Art, we believe in a better way. A way where your tools are visible, accessible, and organized in a system that moves seamlessly from your shop to your work vehicle and back again. That’s why I want to share my personal journey of designing and building a mobile tool-storage system that delivers on all these fronts.

My Tool-Storage Philosophy: Visibility, Accessibility, and Mobility

My journey began with a simple desire: to see all my tools and retrieve any of them with a single, fluid motion. No more digging through drawers, unstacking heavy boxes, or wasting precious time on unnecessary actions. This philosophy guided every step of my design process.

tool storage boxes in different sizes

tool storage boxes in different sizes

Caption: A glimpse into my workshop, where each tool has its designated place.

Why I Chose a Modular Cart System

I experimented with various toolbox systems but found myself yearning for more freedom and customization. That’s when the idea of a modular cart system clicked.

These carts offer the following benefits:

- Customization: I can arrange my tools according to my workflow, regardless of the brand or size.

- Portability: The carts effortlessly move from my shop to my work van, thanks to their sturdy casters and secure locking mechanisms.

- Organization: Each cart is dedicated to a specific tool category – compressor cart, cordless cart, corded tool cart, and a miter saw cart, minimizing clutter and search time.

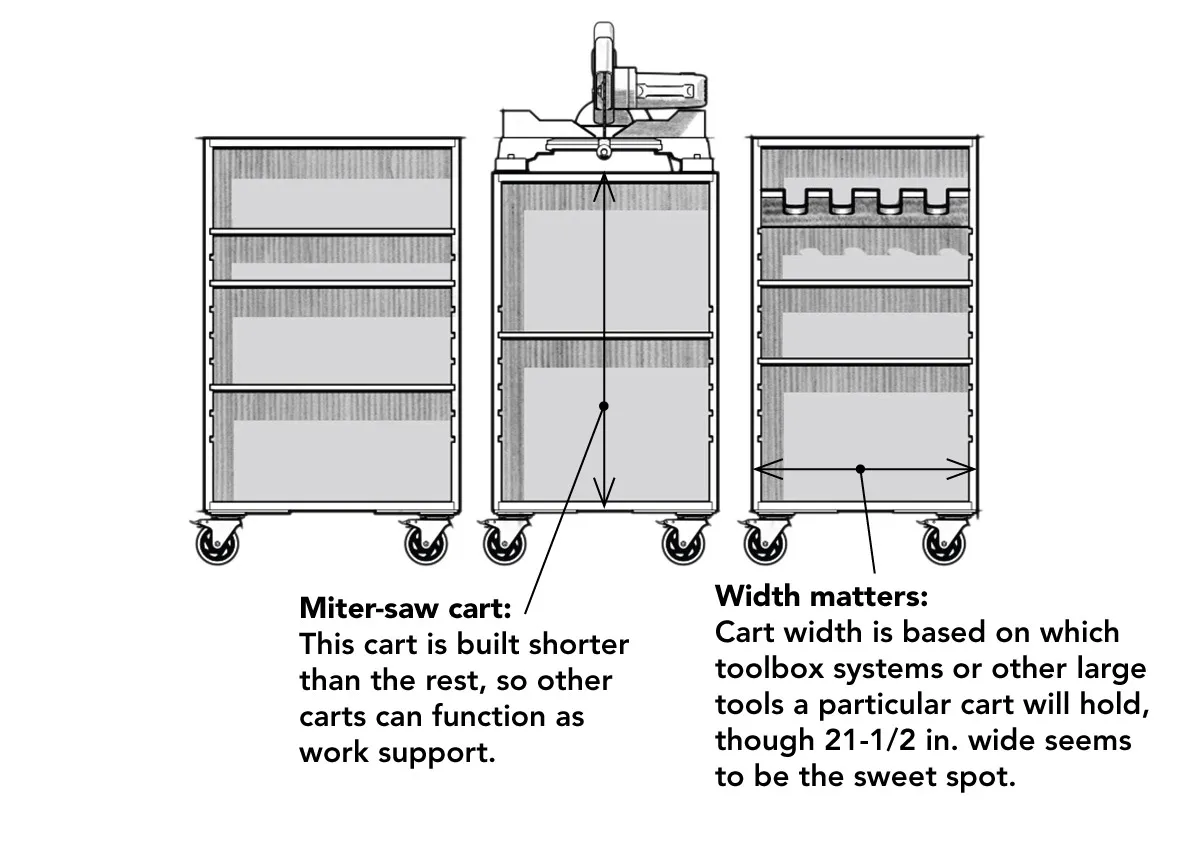

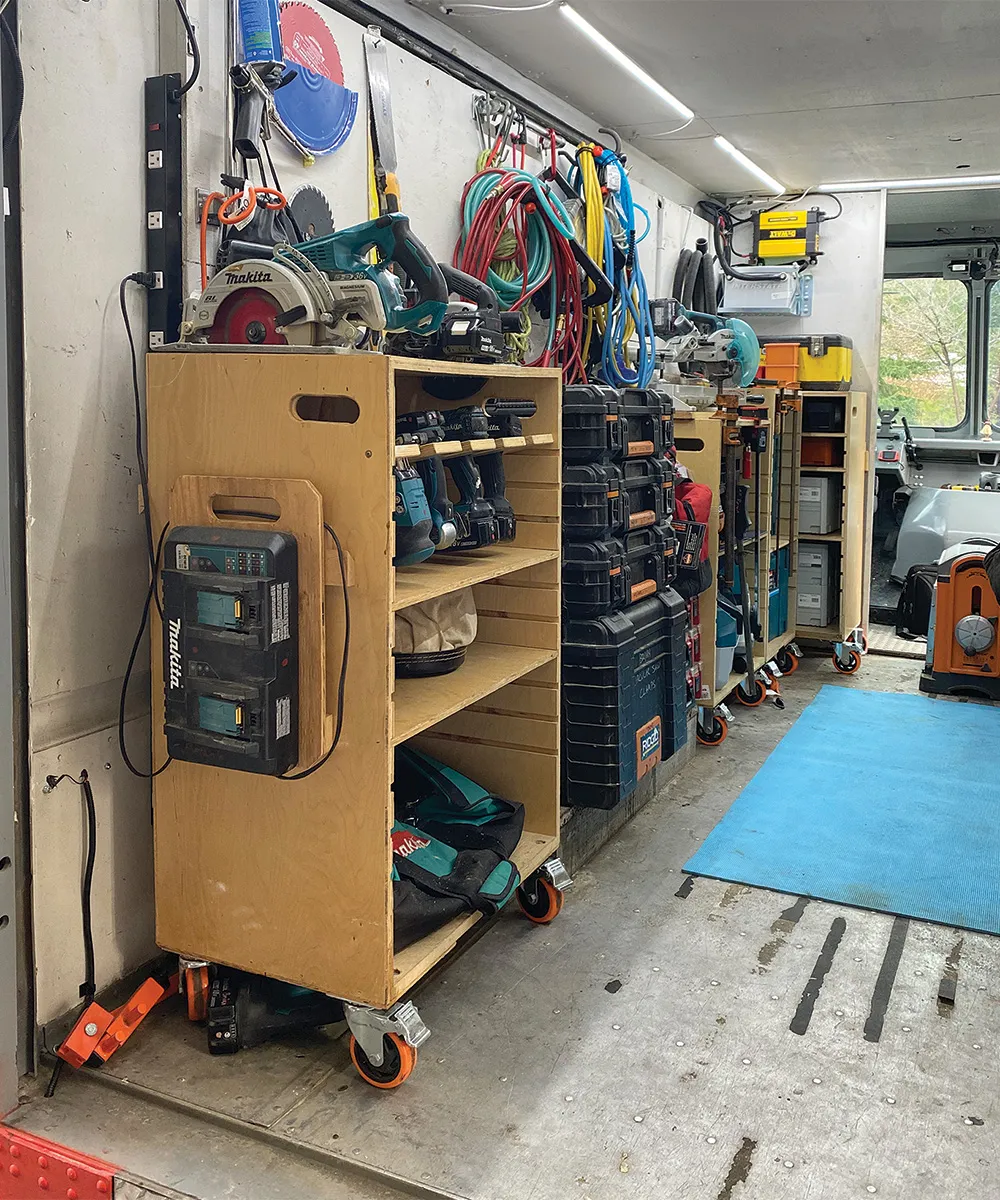

set up for making cuts in a van

set up for making cuts in a van

Caption: My work van transformed into a mobile workshop.

Designing the Ideal Cart: Key Considerations

- Shelf Spacing: I measured my existing toolboxes to determine optimal shelf heights, ensuring everything fits snugly.

- Cart Width: The carts are designed to fit comfortably within my work van, maximizing space utilization.

- Accessibility: I opted for open shelves instead of drawers for instant tool visibility.

- Versatility: The carts double as a miter saw stand – talk about efficient use of space!

illustration of the tool-storage system

illustration of the tool-storage system

Caption: A visual representation of the tool-storage system’s layout within the van.

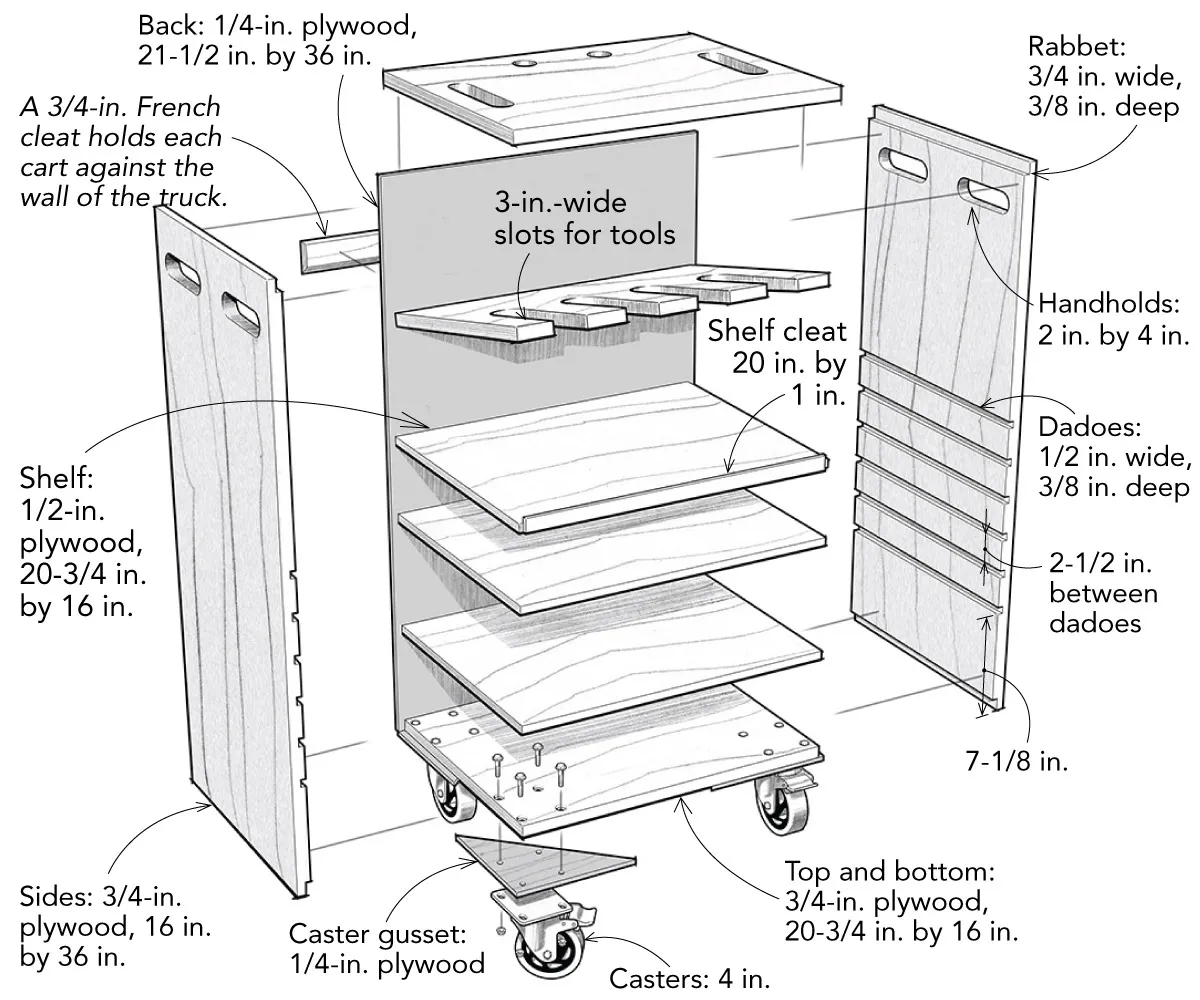

Building the Modular Job Box: A Step-by-Step Guide

Materials You’ll Need:

- Plywood

- Construction screws

- Wood glue

- Casters

- Shelf pins (optional)

Tools for the Job:

- Table saw

- Circular saw (optional)

- Drill

- Screwdriver

- Measuring tape

- Pencil

- Safety glasses

Construction Process:

- Cut the Plywood: Begin by cutting the plywood pieces for the sides, top, bottom, and shelves according to your desired dimensions.

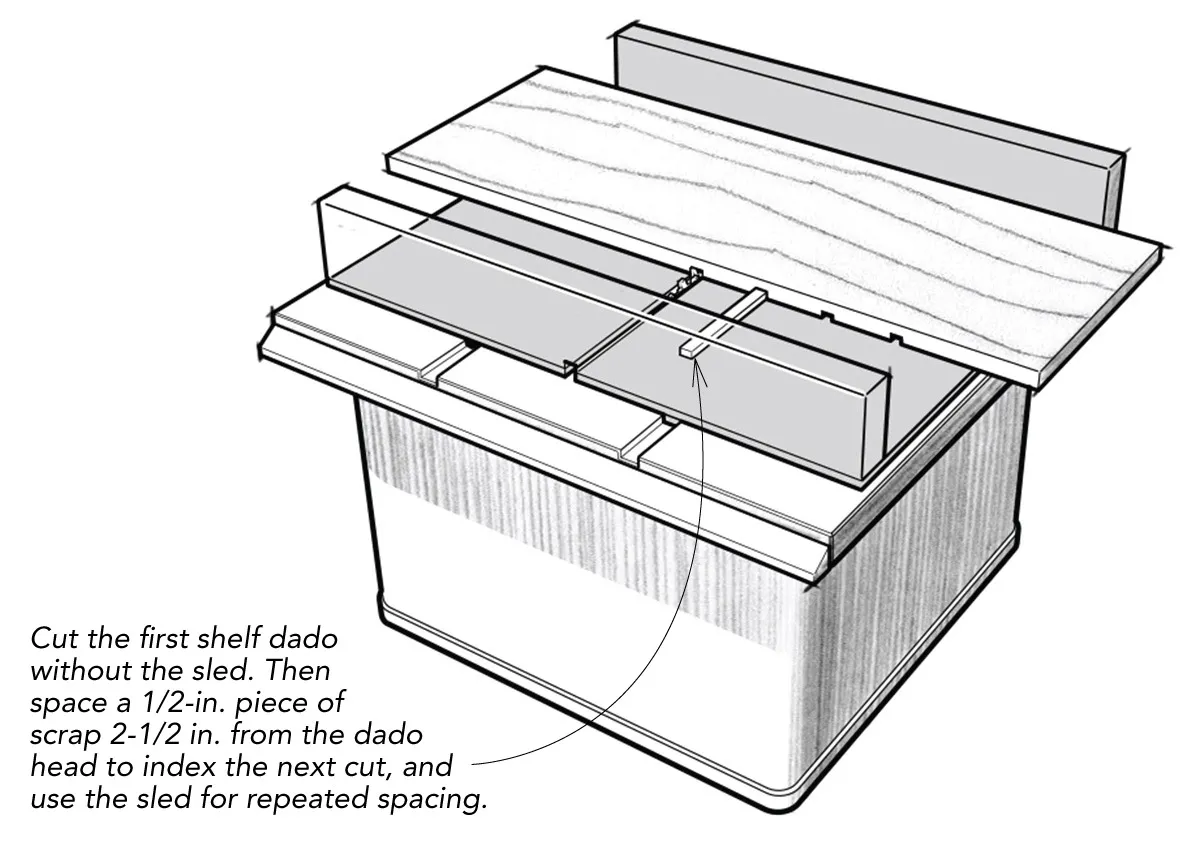

- Create Rabbets and Dadoes: Use a table saw to cut rabbets along the edges of the side pieces to accommodate the top and bottom panels. You can also cut dadoes for the shelves if desired.

- Assemble the Box: Apply wood glue to the rabbets and dadoes, then secure the top, bottom, and shelves to the side pieces using screws.

- Reinforce the Corners: Strengthen the bottom corners where the casters will be mounted using plywood triangles and screws.

- Attach the Casters: Install the casters to the bottom of the box, ensuring they are securely fastened.

tool-storage box plan

tool-storage box plan

Caption: A detailed plan for building the tool storage box.

Tips for Success:

- Accuracy is Key: Take precise measurements and ensure all cuts are square for a sturdy and well-fitting box.

- Pre-drilling is Your Friend: Pre-drill screw holes, especially when working with plywood, to prevent splitting.

- Consider Shelf Pins: Use shelf pins for adjustable shelf heights if your storage needs change over time.

cutting shelf dadoes on the tablesaw

cutting shelf dadoes on the tablesaw

Caption: Using a table saw to create precise dadoes for the shelves.

Customizing Your Carts: Unleash Your Inner Craftsman

Once the basic boxes are built, it’s time for the fun part – customization!

- Tool Holders: I started with simple upside-down tees but found that angled plywood slots provide better tool retention and accessibility.

- Dog Holes: Adding dog holes to the cart tops allows for versatile workholding and assembly options.

- Fastener Storage: Shallow wells or compartments are perfect for organizing screws, nails, and other small fasteners.

- Handholds: Instead of two, I opted for four handholds on each cart for easier maneuvering.

tool holders

tool holders

Caption: Customized tool holders keep everything organized and within easy reach.

Rehabbing a Step Van: My Ultimate Mobile Workshop

My mobile tool-storage system truly shines in my refurbished 1977 Chevy Grumman step van. This vintage beauty, with its spacious cargo area and rear ramp door, is my dream mobile workshop.

holes in top of box for tools

holes in top of box for tools

Caption: Customized compartments on the cart’s top provide dedicated storage for specific tools.

1977 Chevy Grumman

1977 Chevy Grumman

Caption: My restored 1977 Chevy Grumman step van – a craftsman’s dream on wheels.

While the restoration was a labor of love, the result is a customized workhorse that perfectly complements my workflow.

Tips for Maintaining Your Mobile Workshop:

- Regular Cleaning: Wipe down surfaces, remove dust and debris, and keep tools clean and organized.

- Inspect and Tighten: Periodically check for loose screws, bolts, or casters and tighten as needed.

- Protect Your Investment: Consider a weather-resistant sealant or paint to protect your carts from the elements.

1977 Chevy Grumman dash

1977 Chevy Grumman dash

Caption: The interior of my van, showcasing the restored dashboard and the spacious cargo area.

tool-storage system inside the van

tool-storage system inside the van

Caption: The complete tool-storage system seamlessly integrated into the van’s cargo space.

Conclusion: Embrace the Power of Customization

Building a mobile tool-storage system is an ongoing journey of refinement and adaptation. Embrace the process, experiment with different configurations, and customize your setup to perfectly match your individual needs and workflow. Remember, an organized workspace is a productive workspace, and having the right tools at your fingertips empowers you to create your best work.

Now, it’s your turn! What are your biggest tool-storage challenges? What customization ideas inspire you? Share your thoughts and experiences in the comments below.

And don’t forget to explore the Robert Kline Art website for more inspiring DIY projects, crafting tips, and unique handmade gifts for the art enthusiast in your life.