Blog

Building a DIY Folding Sewing Table for Your Craft Room

As an artist who loves working on large-scale projects, I’m always looking for ways to maximize my workspace. My craft room, like many of yours, presents unique challenges, especially when tackling projects like oversized dog beds or elaborate quilts. That’s when I realized the need for a spacious yet practical solution – a DIY folding sewing table.

This guide will walk you through creating your own expansive sewing table without breaking the bank. We’ll be using affordable materials and simple techniques, proving that you don’t need a fancy workshop to build furniture that’s both functional and stylish. Let’s transform your creative space, one cut of plywood at a time!

Gathering Your Materials

Before we begin, let’s gather our tools and materials. You’ll need:

- 1 Sheet Maple Veneer Plywood (8 ft x 4 ft): This provides a sturdy and spacious surface for all your sewing endeavors.

- Skinny Pine Trim Moulding Strips: These add a polished look to the plywood edges and are surprisingly easy to work with.

- 6 Ikea Desk Legs (or similar): Opt for affordable and sturdy legs that can be easily attached.

- Finishing Nails: Choose a size that’s appropriate for your trim thickness.

- Wood Glue: This helps secure the trim for a professional finish.

- Wood Putty: Use this to fill any nail holes and gaps for a seamless look.

- Sandpaper (various grits): Essential for smoothing the wood before finishing.

- Dark Walnut Minwax Stain (or your preferred color): This adds warmth and protects the wood.

- Polyurethane Sealer: A protective topcoat that enhances the wood’s natural beauty.

- Measuring Tape: Accuracy is key!

- Pencil: For marking your cuts.

- Saw (circular saw or jigsaw): For cutting the plywood to size.

- Miter Saw (optional but recommended): For making precise angled cuts on the trim.

- Hammer: For driving in those finishing nails.

- Nail Set: To countersink the finishing nails for a smooth finish.

- Pliers: Helpful for holding small nails while hammering.

- Paint Brushes or Rags: For applying stain and sealer.

- Safety Glasses and Gloves: Protect yourself throughout the process.

Step-by-Step Building Guide

1. Preparing the Plywood

-

Measure and Mark: Determine the ideal dimensions for your sewing table based on your available space and project needs. Remember, bigger is often better!

-

Cutting: Carefully cut the plywood sheet to your desired size using a circular saw or jigsaw. If possible, have the plywood cut at the store to save time and potential hassle.

Pro Tip: When working with large sheets of plywood, it’s helpful to have an extra set of hands for support and guidance.

Cutting Plywood for Sewing Table | TheBorrowedAbode.com

Cutting Plywood for Sewing Table | TheBorrowedAbode.com

2. Attaching the Legs

-

Positioning: Place the Ikea legs (or your chosen legs) at the corners and center points of the plywood, ensuring even weight distribution.

-

Securing: Attach the legs securely to the plywood using screws. Predrill pilot holes to prevent the wood from splitting.

Tip: Consider using furniture glides on the bottom of the legs to protect your floors and allow for easy movement.

Attaching Ikea Legs to Sewing Table Plywood | TheBorrowedAbode.com

Attaching Ikea Legs to Sewing Table Plywood | TheBorrowedAbode.com

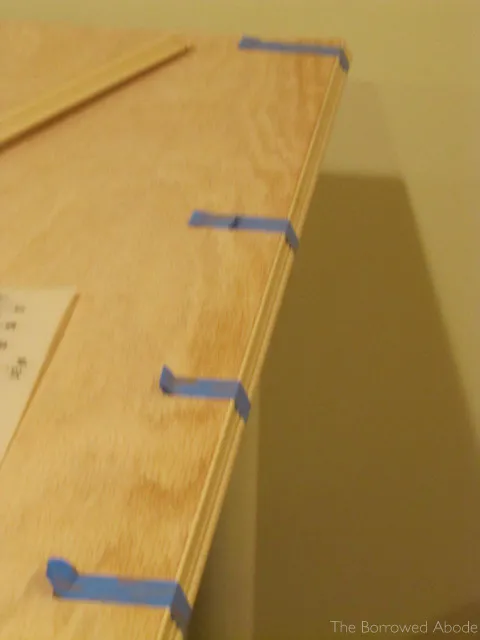

3. Finishing the Edges with Trim

-

Measuring and Cutting the Trim: Measure the edges of your plywood tabletop and cut the trim to size using a miter saw (for angled corner cuts) or a hand saw.

-

Gluing and Taping: Apply a thin line of wood glue to the back of each trim piece, carefully align it with the edge of the plywood, and secure it with painter’s tape. Let it dry for at least 24 hours.

-

Nailing and Countersinking: Once the glue is dry, reinforce the trim by hammering finishing nails along its length. Use a nail set to countersink the nail heads below the surface of the trim.

Tip: For a professional touch, apply wood putty to the countersunk nail holes and any gaps in the trim. Allow the putty to dry completely, then sand it smooth for a flawless finish.

Gluing Trim to Plywood Table Top | TheBorrowedAbode.com

Gluing Trim to Plywood Table Top | TheBorrowedAbode.com

Countersink Trim Nails with another Nail | TheBorrowedAbode.com

Countersink Trim Nails with another Nail | TheBorrowedAbode.com

Trim Putty to fill gaps Sewing Table | TheBorrowedAbode.com

Trim Putty to fill gaps Sewing Table | TheBorrowedAbode.com

4. Sanding and Staining

-

Sanding: Smooth the entire surface of the tabletop, including the trim, using an electric sander followed by hand sanding. Start with a coarser grit sandpaper and gradually work your way up to a finer grit for a velvety smooth finish.

-

Staining: Apply an even coat of Dark Walnut Minwax stain (or your chosen stain color) to the tabletop, following the manufacturer’s instructions. Allow the stain to penetrate for the recommended time, then wipe away any excess.

Tip: Test the stain on a hidden area of the plywood or a scrap piece to ensure you like the color and finish before applying it to the entire tabletop.

Simple DIY Large Sewing Table | The Borrowed Abode

Simple DIY Large Sewing Table | The Borrowed Abode

5. Sealing for Protection

- Applying Sealer: Once the stain is completely dry, apply a protective coat of polyurethane sealer to the tabletop using a brush or foam applicator. Follow the manufacturer’s instructions for drying time between coats.

- Final Touches: Once the final coat of sealer is dry, inspect your handiwork for any imperfections. Lightly sand any rough spots and wipe the tabletop clean.

Easy Trimmed Edges on Sewing Table | The Borrowed Abode

Easy Trimmed Edges on Sewing Table | The Borrowed Abode

Conclusion

Congratulations! You’ve just built a spacious and sturdy sewing table that will elevate your crafting experience. Not only does it provide ample space for large-scale projects, but it also adds a touch of handmade charm to your craft room.

Imagine the creative possibilities that await with your new sewing table! From intricate quilting projects to bold fashion designs, you’ll have the perfect workspace to bring your visions to life.

Feeling inspired? Share your own sewing table creations or crafting adventures with us in the comments below. And be sure to explore the unique handmade gifts and crafting supplies available on Robert Kline Art – the perfect way to add a touch of personal style to your creative space. Happy crafting!

Hand Built Sewing Cutting Table | The Borrowed Abode

Hand Built Sewing Cutting Table | The Borrowed Abode