Blog

Building Custom Bookcase Doors with the Kreg Pocket-Hole Jig 320

Hey there, fellow craft enthusiasts! Robert Kline here, and I’m excited to share a project that’s close to my heart: building beautiful, custom bookcase doors using the incredible Kreg Pocket-Hole Jig 320.

Have you ever looked at a bookcase and thought, “It needs something… more”? Maybe it’s overflowing with electronics, or perhaps you just crave a cleaner, more polished aesthetic. Well, my friends, a set of well-crafted doors might just be the missing piece!

In this step-by-step guide, I’m going to walk you through the entire process – from measuring and cutting to assembly and finishing. We’ll even cover how to install those doors with sleek, frameless hinges for a truly professional look. And the best part? You can easily adapt these techniques to revamp cabinets, bathroom vanities, and more!

Gathering Your Tools and Materials

Before we dive in, let’s make sure you have everything you need for a smooth and successful build. Here’s a list of the essentials:

Tools:

- Measuring Tape

- Chop Saw (optional – you can have the home improvement store make the cuts for you)

- Cordless Drill

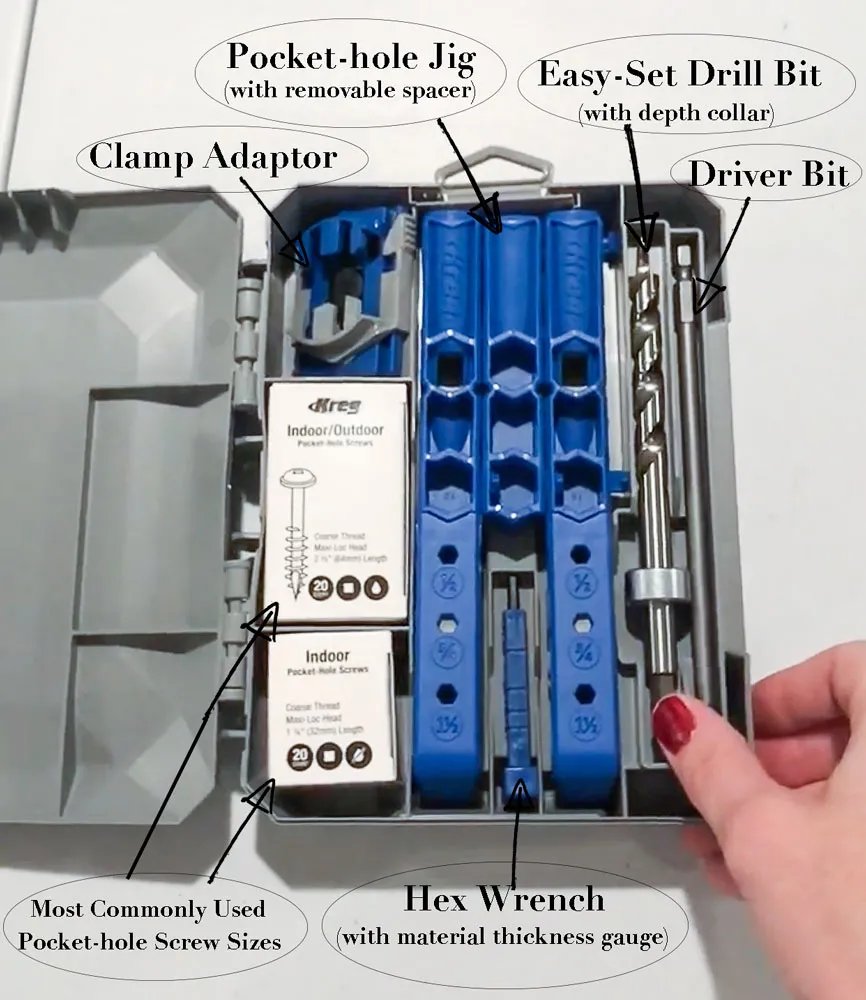

- Kreg Pocket-Hole Jig 320

- Kreg Concealed Hinge Jig

- Clamps

Materials:

- Wood Glue

- 1″ pocket-hole screws

- 1 1/4″ pocket-hole screws (these come with the Kreg Pocket-Hole Jig 320 kit)

- 2 – Full Overlay Frameless Hinge Sets

- 4 – 4″ long pieces of scrap pine (optional – for bookcase frame overhang)

- 8 – 1″ screws (optional – for bookcase frame overhang)

- 1×3 Boards (amount determined by your measurements – see Step 2)

- 1/2″ Plywood (amount determined by your measurements – see Step 2)

- Paint or Stain (in your desired color)

- Hardware (knobs or pulls)

Step-by-Step Guide to Building Your Doors

Step 1: Measuring for a Perfect Fit

Using your trusty measuring tape, carefully measure the opening where your doors will go. Write down the width and height – accuracy is key here!

Step 2: Calculating Your Wood Needs

Now it’s time to determine exactly how much wood to buy. I like to sketch out a simple diagram of the door and use this handy formula:

- Stiles (vertical pieces): (Door Height – (2 x Thickness of Rails))

- Rails (horizontal pieces): (Door Width – (2 x Thickness of Stiles) + (2 x Overlap Amount))

- Plywood Inset: (Door Height – (2 x Thickness of Rails) x (Door Width – (2 x Thickness of Stiles))

Pro Tip: Most home improvement stores will make cuts for you. Having them cut your 1×3 boards and plywood to size can save you time and ensure precise measurements.

Step 3: Creating the Door Frame

With your wood cut to size, lay out the pieces as they’ll be assembled. Ensure your rails are perfectly flush with the shorter edges of the plywood. Even a tiny discrepancy can lead to gaps later on, so trim the stiles if needed.

" alt="Laid out wood pieces

" alt="Laid out wood pieces

Step 4: Mastering the Pocket Hole

The Kreg Pocket-Hole Jig 320 is a game-changer for creating strong, invisible joints. Here’s how to use it:

- Adjust the Jig: Remove the middle spacer and adjust the jig to the 3/4″ thickness of your 1×3 boards.

- Set the Depth Collar: Use the hex wrench to adjust the depth collar on the drill bit to the 3/4″ mark.

- Secure and Drill: Clamp your workpiece securely, then drill two pocket holes on each end of the rails.

- Adjust for Plywood: Change the jig and depth collar settings to 1/2″ for your plywood. Drill three pocket holes on each long side and two on each short side.

" alt="Using Kreg Jig 320

" alt="Using Kreg Jig 320

Step 5: Assembling the Door

- Creating the Inset: Use cardstock stacks or a magazine (about 1/4″ thick) to elevate the plywood inset. Apply wood glue to the short edges of the plywood, then align and clamp the rails.

- Securing the Frame: Attach the plywood to the rails using 1″ pocket-hole screws. Then, glue and clamp the stiles to the plywood and secure them to the rails with 1 1/4″ pocket-hole screws. Finally, drive 1″ pocket-hole screws from the plywood inset into the stiles.

" alt="Assembled door

" alt="Assembled door

Pro Tip: When driving screws into the stiles, start with the inner pocket hole, then gently drive in the outer screw. This helps prevent splitting.

Step 6: Installing the Hinges

- Creating Hinge Holes: Use the Kreg Concealed Hinge Jig to drill perfect hinge holes. Clamp the jig to your door edge (I like the ‘3’ setting) and use the hole-boring bit to create the hole.

- Pre-Drilling for Screws: With a small drill bit (1/16″), pre-drill pilot holes for the hinge screws using the guides in the Hinge Jig.

" alt="Final product of the doors

" alt="Final product of the doors

Step 7: Prepping the Bookcase (If Needed)

If your bookcase has a lip or overhang, you’ll need to attach spacers to the inside walls where the hinges will be installed. Use 4″ pieces of scrap pine and secure them with screws.

Step 8: Mounting the Doors

- Positioning and Securing: Align the door with a 1/4″ overhang at the top. Attach the top screw of the top hinge to the spacer, followed by the top screw of the bottom hinge.

- Adjusting and Finalizing: Close the door to check for clearance issues. If needed, use the adjustment screw closest to the bookcase frame to fine-tune the fit. Once you’re happy, install the remaining hinge screws. Repeat for the other door.

Step 9: Adding Finishing Touches

- Sanding and Prepping: Lightly sand the doors and pre-drill holes for your chosen hardware.

- Painting or Staining: Apply your desired finish, allowing ample drying time between coats.

- Installing Hardware: Attach your knobs or pulls – and admire your handiwork!

" alt="Final look

" alt="Final look

Conclusion

Congratulations – you’ve just transformed your bookcase with custom doors! Not only have you enhanced its functionality, but you’ve also added a touch of your own personal style. Remember, the techniques we covered today can be applied to a wide range of projects, so don’t be afraid to get creative!

For more inspiring DIY projects, tips, and techniques, be sure to explore the rest of the Robert Kline Art website. And if you decide to build your own bookcase doors, we’d love to see your creations! Share your projects and connect with a community of passionate crafters in the comments below.